Description

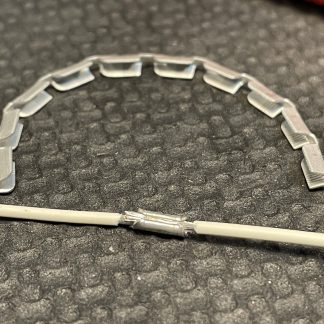

Open barrel crimp splice with serrations made from brass with a tin plating. This open barrel crimp splice is suitable for use in applications where splicing is required.

All Crimps are genuine TE brand. Made in USA.

CMA = Circular Mil Area

For best results use with Knipex Crimping Pliers

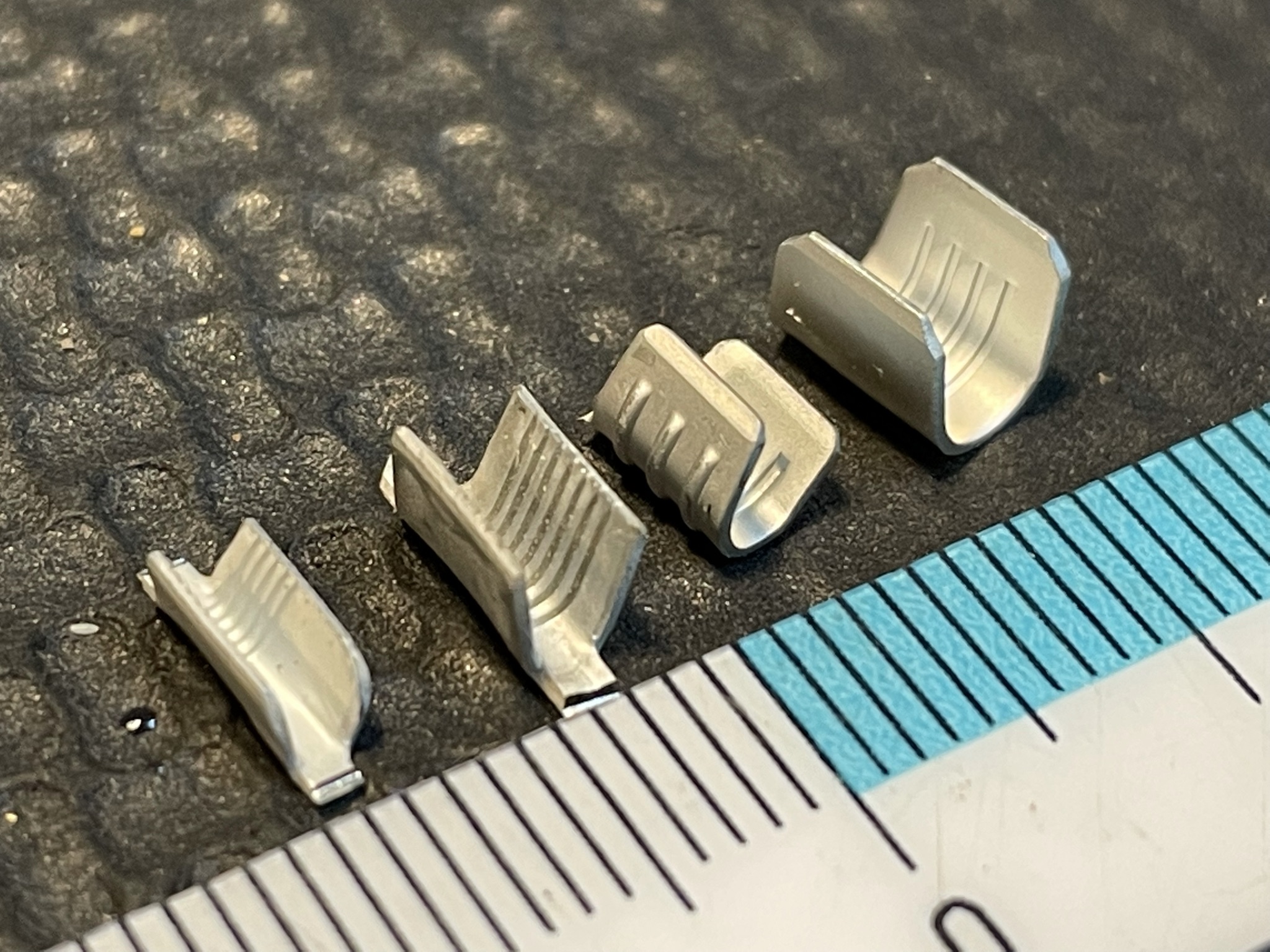

Sizes Available

| X-Small | 400-1500 CMA |

| Small | 1500-5000 CMA |

| Medium | 4000-9000 CMA |

| Large | 7000-13000 CMA |

Common wire sizes CMA

Add together to get total CMA to choose correct size splice (eg 16ga + 20ga + 20ga + 20ga = 2575CMA + 1006CMA +1006CMA +1006CMA = 5593CMA = Medium Splice)

| AWG | Area (mm²) | CMA |

| 24 | 0.205 | 404 |

| 20 | 0.51 | 1006 |

| 18 | 0.79 | 1559 |

| 16 | 1.305 | 2575 |

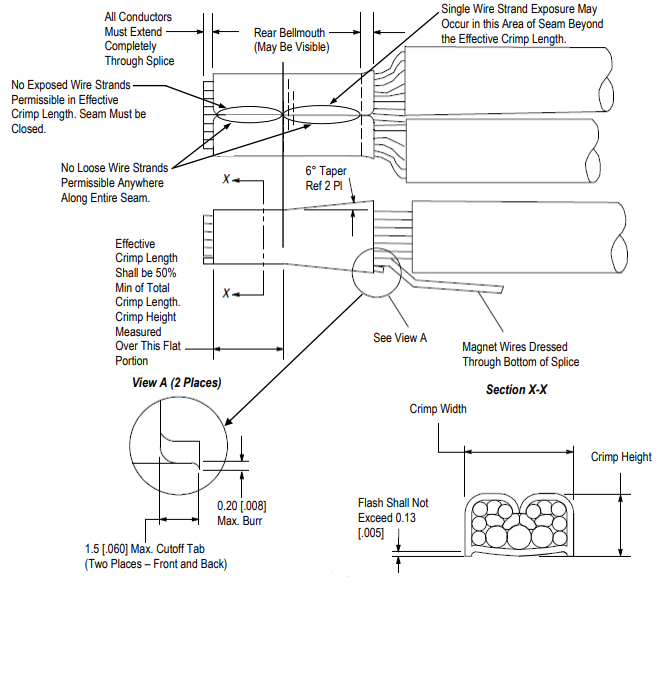

Crimped Splice Requirements:

The illustration below shows the crimp features required for typical pigtail and thru type splices after termination.

A. Crimp Length

For optimum crimp length effectiveness, the crimp must be within the area shown and must meet the

crimp dimensions provided. Effective crimp length shall be defined as that portion of the splice,

excluding tapers, fully formed by the crimping tool.

B. Crimp Tapers

Top and bottom crimp tapers shall conform to the dimensions given in Figure 3. Crimp tapers contribute to

crimp effectiveness and reduce the risk of nicked and/or broken conductor strands due to sharp material

edges at the ends of the splice.

C. Cutoff Tabs

Cutoff tabs shall not exceed the dimension shown in View A.

D. Cutoff Burrs

Cutoff burrs shall not exceed the dimension shown in View A.

E. Wire Barrel Flash

Wire barrel flash, which can be caused by incorrect set up and/or worn and broken crimp tooling, shall not

exceed the dimension shown in Section X-X.

F. Conductor Extension

Conductors must extend completely through the splice. Excess magnet wire and lead wire strands will be

trimmed off by the application equipment as shown.

G. Splice Seam

The splice seam must be closed with no evidence of loose wire strands visible in the seam as shown in

Figure 3. Single wire strand exposure may occur in seam beyond effective crimp length. See Figure 3.

H. Tensile Strength

Crimp quality shall be judged solely on proper crimp width, crimp height, and conformance to the

requirements shown. When crimped as specified, crimp tensile strength will be approximately 70% off the tensile strength of the smallest wire in the splice.

Reviews

There are no reviews yet.